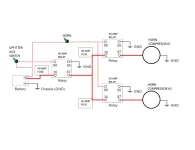

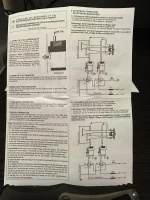

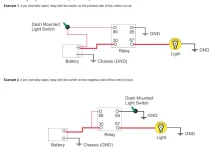

Thanks for the input. My sketch above shows the proposed alignment. Currently power is coming from a 15 Amp upfitter switch power source split to the power side of the two relays/compressors on the right, and it does drive the horns sometimes (very lame by the installer). Yeah, might be better to find a 60 amp relay. Worst case it will blow the 40 amp fuse, and I kind of doubt these small compressors will draw 30 amps (very large low-loss cable going to the compressors). I have a clamp meter which can measure DC amps so I can check the actual current draw. My biggest concern is the logic of using one relay to energize the power side of the two downstream relays, thought I can't see any issue aside from the fact that if the compressors really draw 30 amps each, it will blow the upstream fuse / relay. At first I wanted to just have the horn to the upfitter switch, but the installer thought better to be connected to the horn circuit to avoid accidental actuation. For these relays, supposedly hot side or ground side actuation shouldn't matter according to the sketch here for normally open relays. The kit didn't come with a switch. Maybe with real power coming to the compressors the horns will be louder, but even with only 7.5 amps going to each they are really loud. Oh I corrected my original question as I used the word solenoid instead of relay. There are no solenoids.